CEM-3

主營(yíng)生產(chǎn)通訊設(shè)備、數(shù)碼家電、電腦等產(chǎn)品之主要電子基礎(chǔ)材料:銅箔基板,提供給客戶滿意的產(chǎn)品選擇與售后服務(wù)。

所屬分類:

產(chǎn)品關(guān)鍵詞:

儀器儀表

信息家電

汽車電子

關(guān)鍵詞:

普通FR-4 | 半固化片 | 無(wú)鉛兼容FR-4 | 無(wú)鹵兼容FR-4

產(chǎn)品描述

電子資訊工業(yè)近幾年來(lái)在中國(guó)的迅速發(fā)展下,結(jié)合各種相關(guān)產(chǎn)業(yè),已經(jīng)成為中國(guó)蓬勃發(fā)展、舉足輕重的新興產(chǎn)業(yè)。

江蘇諾德正是藉此信息產(chǎn)業(yè)化發(fā)展之平臺(tái),以專業(yè)制造電子基礎(chǔ)材料為優(yōu)勢(shì),于2007年開(kāi)始建立銅箔基板生產(chǎn)基地,憑借優(yōu)秀的科技人才與創(chuàng)新的研發(fā)能力,配套發(fā)展生產(chǎn)通訊設(shè)備、數(shù)碼家電、電腦等產(chǎn)品之主要電子基礎(chǔ)材料:銅箔基板,提供給客戶滿意的產(chǎn)品選擇與售后服務(wù)。

|

CEM-3 |

|

|

|||||

|

|

|||||

|

(UL ANSI:CEM-3) |

|||||

|

|

|||||

|

特點(diǎn)

|

應(yīng)用領(lǐng)域 |

||||

|

|

|||||

|

FEATURES

|

APPLICATIONS |

||||

|

|

|||||

|

GENERAL PROPERTIES |

|||||

|

Test Item |

Test condition |

Units |

Standard value |

Typical value |

|

|

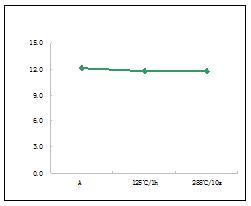

1.Peel Strength , IBS/IN,Minimum,1 OZ |

|

IBS/IN |

|

|

|

|

As received |

A |

≥8.0 |

12.5 |

||

|

After thermal stress |

A |

≥8.0 |

12.5 |

||

|

2. Volume resistivity ,Minimum |

E-24/125 |

MΩ.cm |

≥103 |

≥106 |

|

|

3. Surface resistivity , Minimum |

E-24/125 |

MΩ |

≥103 |

≥106 |

|

|

4.Water absorption , Maximum |

E-1/105+des |

% |

≤0.50 |

0.23 |

|

|

5.Dielectric Breakdown, Minimum |

D-48/50 D-0.5/23 |

Kv |

≥40 |

42 |

|

|

6. Flexural strength ,Minimum |

|

Mpa |

|

|

|

|

Length direction |

A |

≥276 |

390 |

||

|

Cross direction |

A |

≥186 |

320 |

||

|

7.Arc resistance ,Minimum |

D-48/50 |

S |

≥60 |

115 |

|

|

8.Flammability |

A |

S |

UL-94V0 |

UL-94V0 |

|

|

9. Permittivity 1MHZ ,Maximum |

A |

|

≤5.4 |

4.6 |

|

|

10.Loss tangent 1MHZ ,Maximum |

A |

--- |

≤0.035 |

0.02 |

|

|

11.Thermal stress 260℃,10sec( Minimum ) |

|

--- |

|

|

|

|

Non etched specimen |

A |

NO DEFECT |

NO DEFECT |

||

|

Etched |

A |

NO DEFECT |

NO DEFECT |

||

|

12. TG(DSC,℃) |

A |

℃ |

≥135 |

136 |

|

|

13. CTI,V |

TEC-112 |

V |

≥175 |

200 |

|

|

Note: |

|||||

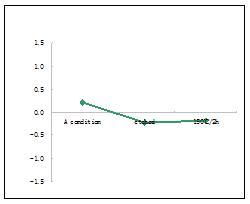

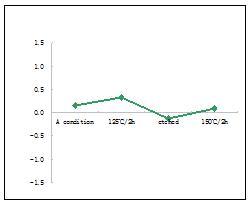

Warpage of Warpage of

(No-treating) (After treating:125℃ 2hr)

Peel strength

※Specimen T hickness:1.6mm single side board

|

PURCHASING INFORMATION |

|

|

||

|

Thickness |

Copper foil |

Standard Size |

|

0.8mm to 3.4mm |

12μm to 105μm |

1041×1245mm(41″×49″) 940×1245mm(37″×49″) |

|

※ Other sheet size and thickness could be available upon request. |

||

合作意向表

Cooperation Intent Form